Lime Mortar Pointing, Lime mortar Repointing

This page is currently being updated

Lime Mortar Guide

Are you are looking for a technical & construction specialist in traditional Lime mortars?

You own a pre 1919 building constructed of stone, are looking to renovate stonework on a building of this era or looking to build a new stone building? Lime mortar is the best construction mortar for use in pre 1919 buildings because such buildings were built in a different way than the rigid buildings of today. Much skill and experience is required in the mixing, application and aftercare (nurturing) of lime mortars. All our lime mortars are manufactured as bespoke, being mixed with specific sands and pozzolans. Lime mortar is increasingly being used in new build stoneworks. We undertake lime mortar stonework and lime mortar pointing March to june and September – November, depending on suitable temperatures for application of lime mortar. We undertake preparations of stonework including removal of portland cement and rebuild stonework where required, between February and December

Background

Before approximately 1930 all stonework, including stone walls and stone buildings were constructed using lime mortar and it is these structures that we consider today to be of heritage significance, requiring specialist heritage craftsperson’s in their maintenance, restorations and reconstructions.

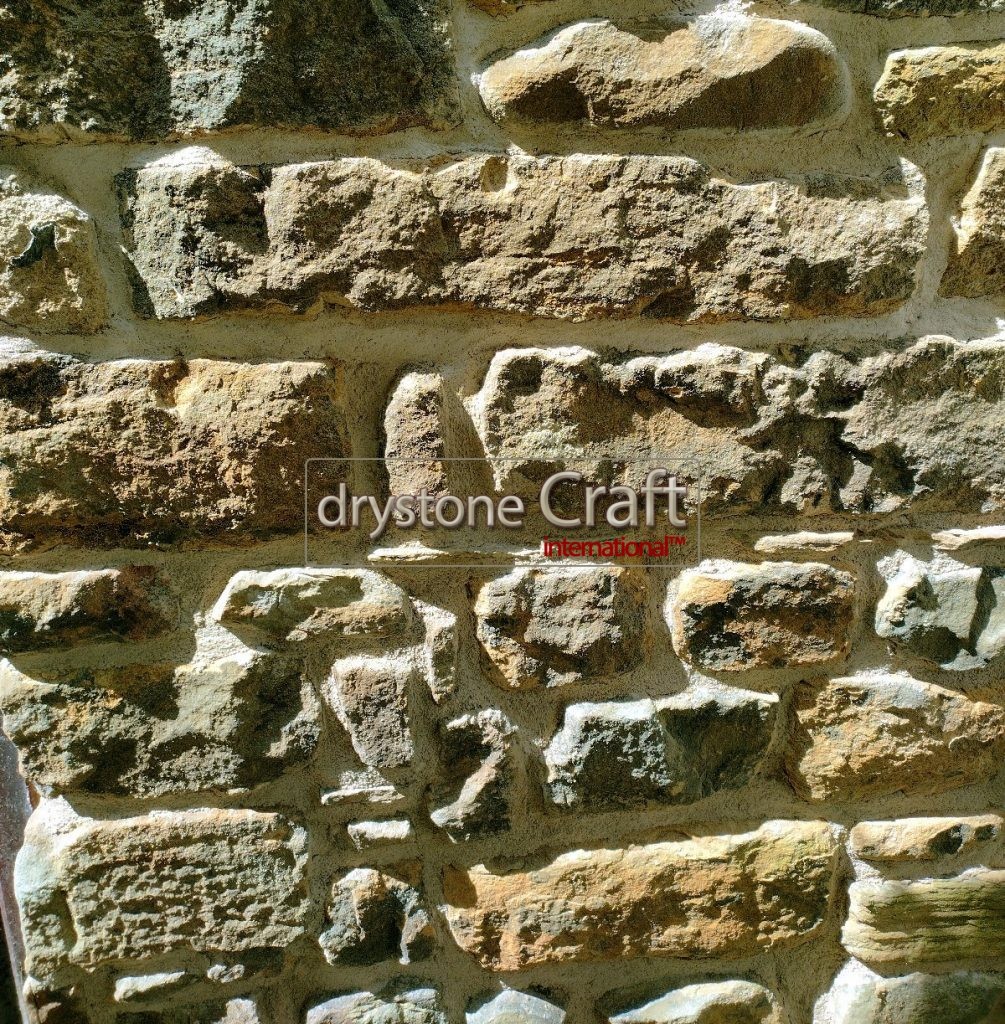

Contrast between our newly restored & lime mortared riverstone stonework and previous Portland cement flush pointing

Considerations

Lime Mortar or Portland Cement for Stone?

When considering bonded stonework always consider the correct use of a specialist lime mortar.

We have undertaken many bonded stonework projects using lime mortar and a number of re-worked contracts where previous contractors had used cement mortar, at considerable strength, the result being ‘blown faces’ of surface stone i.e., the strength of the mortar was high-er than that of the stone and during expansion of stone, the faces of visible stone had fallen off leaving unsightly stonework and a lattice of Portland cement mortar; this effect can be seen in the images opposite, right.

Although lime mortar is more expensive, it is more pliable than cement mortar and enables expansion and contraction of stone; lime mortar also allows the movement of water and water vapour by drawing out ingressed liquid or vapour from stonework. Contact us for more information on lime mortar for your stonework lime pointing requirements

When considering bonded stonework always consider the correct use of a specialist lime mortar. Lime mortars are often unique in their composition to a particular area. Our highly experienced technical and crafts level staff mix our limes and aggregates on site following detailed analysis, matching the volumes of aggregate sands to that of the lime mortar mix that was originally used during the buildings construction.

We do not use lime mortars purchased from the builders merchant for any new build or heritage restoration of lime mortared stonework, as such products are of a mass production mix and therefore not the lime mortar used originally used in the buildings construction.

Where we are engaged in construction of new build using lime mortar, we take samples from nearby buildings and base our lime mortar mix on this original mix specific to the area. We only source our lime from reputable merchants who operate their business in a sustainable and eco friendly manner.

Recessed & cocoa brush textured finished Hot Lime Mortar Pointing

Lime Mortar

Traditional lime mortar, sometimes referred to as natural lime mortar are made using proportions of sand and lime, the lime acting as a binding agent. Throughout history, in the construction of traditional stone buildings and stone walls, there have been two basic types of lime mortar used: hydraulic lime mortar and non hydraulic lime mortar.

Hydraulic Lime Mortar

Hydraulic lime mortars are classified according to there setting times and final strength into three categories: ‘feebly hydraulic’, ‘moderately hydraulic’ and ’eminently hydraulic’, the latter having the fastest setting and highest final stength. Additives called ‘pozzolans’ such as brick dust can be added to hydraulic lime mortars, improving substantially their setting times and final setting strengths.

Non Hydraulic Lime Mortar

Made from almost pure forms of lime and reacts with carbon dioxide in the air, binding and taking a long time to set from a basic strength over several weeks, to full strength which could be a number of years.

Colour tinted Lime mortar

Our lime mortars are colourfast and are made with accurate volume blended coloured sands to achieve consistent colour tints

Textures of Lime mortar

info to be added soon

Why use Lime?

Stonework constructed using lime mortars allows settlement of the structure without cracking of stone or building structures during the settlement period, and for a long period of time the lime mortar remains somewhat pliable, allowing for further settlement. It is widely appreciated that the correct use of lime mortars enables water to be drawn out of the stonework somewhat and harmlessly evaporate – a distinct advantage in wet climates. Many older stone buildings often have thick walls, the stonework being secured by lime; this technique was a widely practiced method of construction and provides evidence of the effectiveness of lime in drawing out damp and water from such buildings. Use of lime fell out of popularity with the emergence of mass manufactured ordinary Portland cement. Modern construction methods still rely heavily on a rigid construction using cement and mortar which enable only a limited movement via expansion joints and impair moisture movement out of the stonework and out of the building.

Damp proof courses, water repellant sealants, cavity walls and cement renders are used widely in modern buildings in an attempt to keep damp and moisture out. Whilst this method of construction may well protect the building from water ingress, it will not enable internal water to escape through the structure. In the case of cement renders on old stone buildings, these will eventually crack and allow ingress of water – cracking being brought about by small movements in the old building. The cement render prevents water from escaping and such water or damp remains in the stonework, eventually working its way into the internal stonework and plaster therefore increasing damp. Although lime mortar is more expensive, it is more pliable than cement mortar and enables expansion and contraction of stone; lime mortar also allows the movement of water and water vapour by drawing out ingressed liquid or vapour from stonework.

.

What is included in the Lime pointing works?

info to be added soon

What does a typical Lime pointing works involve ?

info to be added soon